'5400' 2-8-2 Heavy Mikado 1.6" (7.25" or 7.5" gauge)

The engine and tender were completely disassembled cleaned and glass beaded before each part was primed with an etching primer. This created a perfect base for the black finish coat of 242 Sikkens paint. My 14x27 foot down draft paint booth was loaded several times with parts hung from overhead rails.

The Mikado was detailed as Canadian Pacific # 5400 a P2f series built by Montreal Locomotive Works. I have the original drawings for this engine.

The engine and tender were all assembled just in time for a quick steam up to make sure no leaks were created. Only one was found on the outlet from the axle pump. We then headed for Train Mountain the next day.

A couple of weeks before we left for TM, a lift had to be designed and built to get the engine up into a compartment on the back of my 1-ton dually. The compartment was also designed and built to fit between the back of the cab and the 5th wheel RV. It does make you take turns very carefully. The lift then became the rear bumper of the RV.

CP5400's first run at Train Mountain Triennial.

Images taken June 2006:

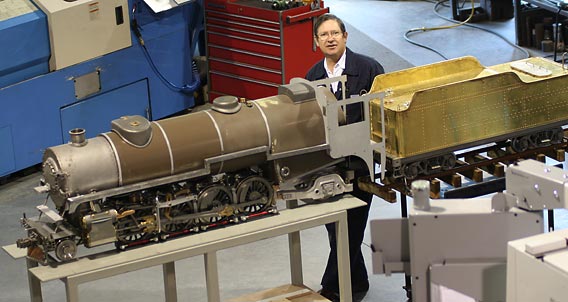

Mikado CP5400 engine and tender have just been completely reassembled after painting and detailing.

They were moved out for this photo-shoot before loading the next day for the trip to Train Mountain in Oregon.

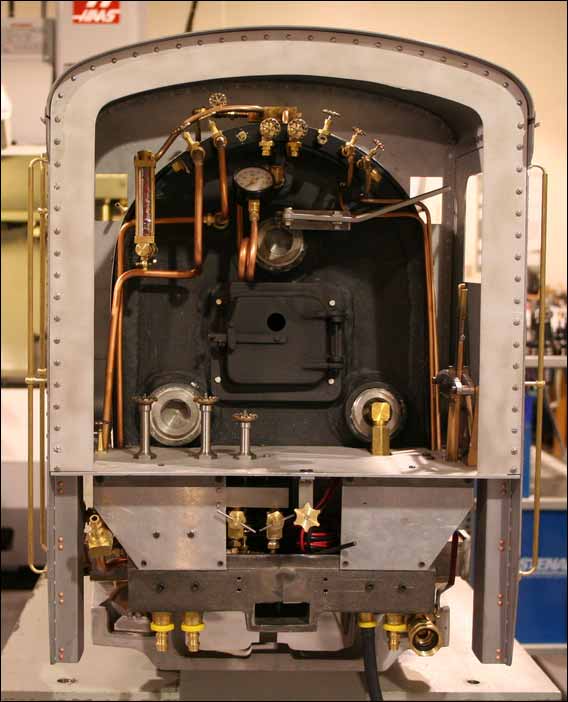

First steam-up after reassembly to do a check for pressure leaks.

Checking the electronic ignition for auto relight functions and checking combustion air adjustment range.

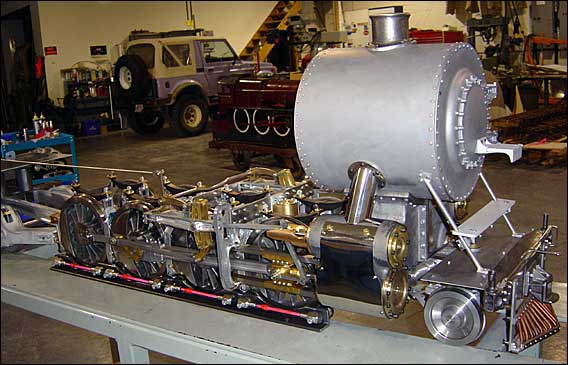

Engine being run on the test table.

Checking the safety relief valves for capacity function.

Images taken May 2006:

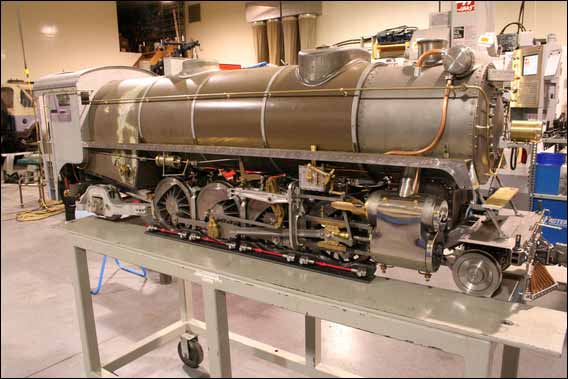

5400 is ready for disassembly to paint and detail.

Fired on diesel, this engine steams beautifully and runs as smoothly as a Rolex.

Images taken Sep 2005:

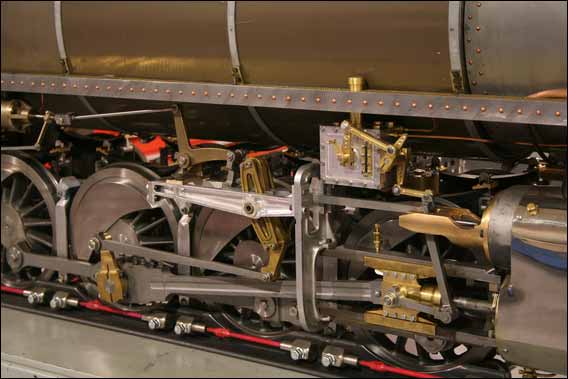

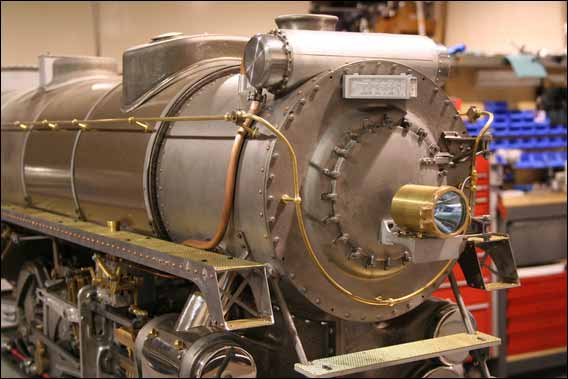

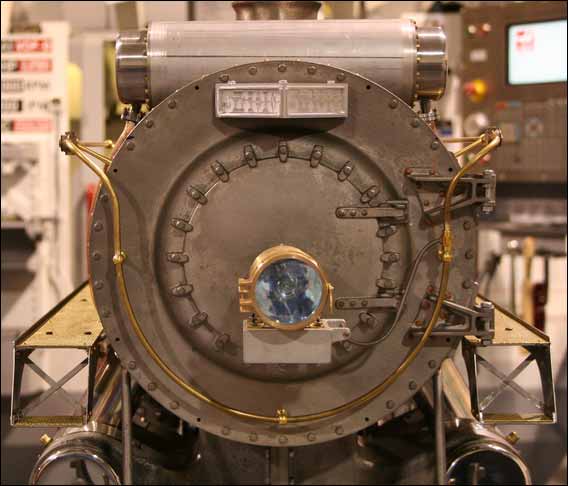

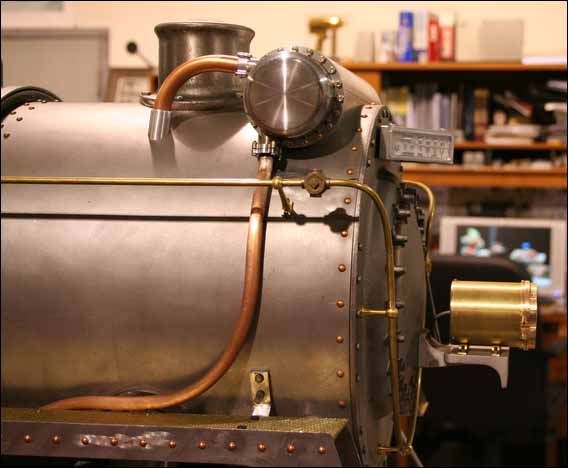

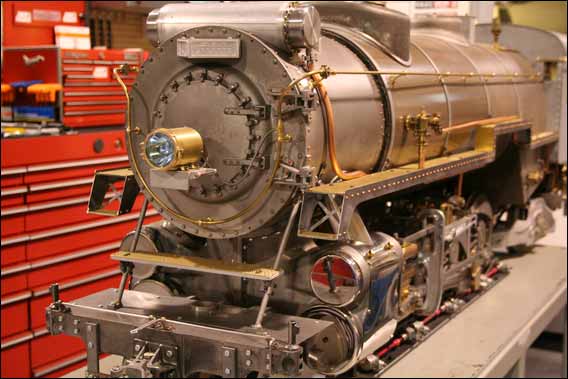

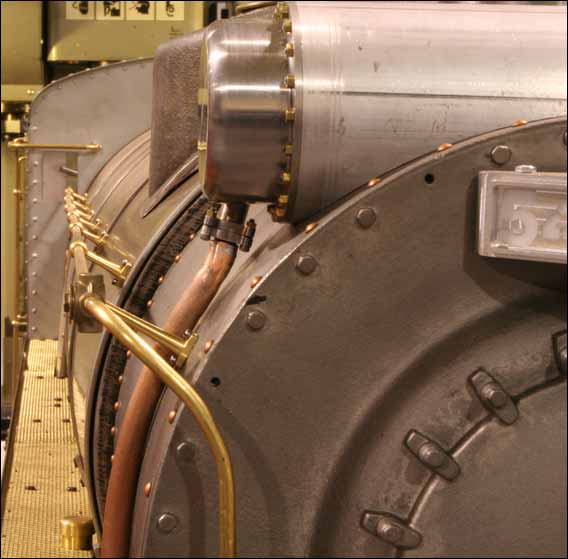

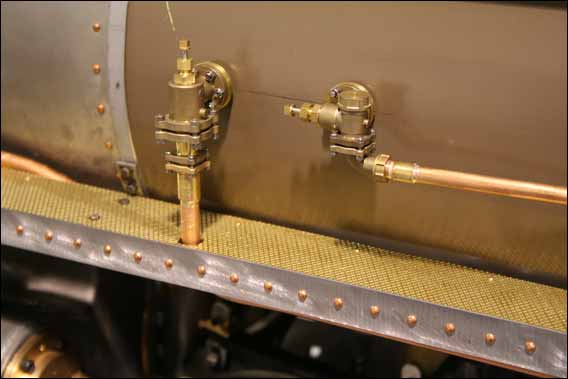

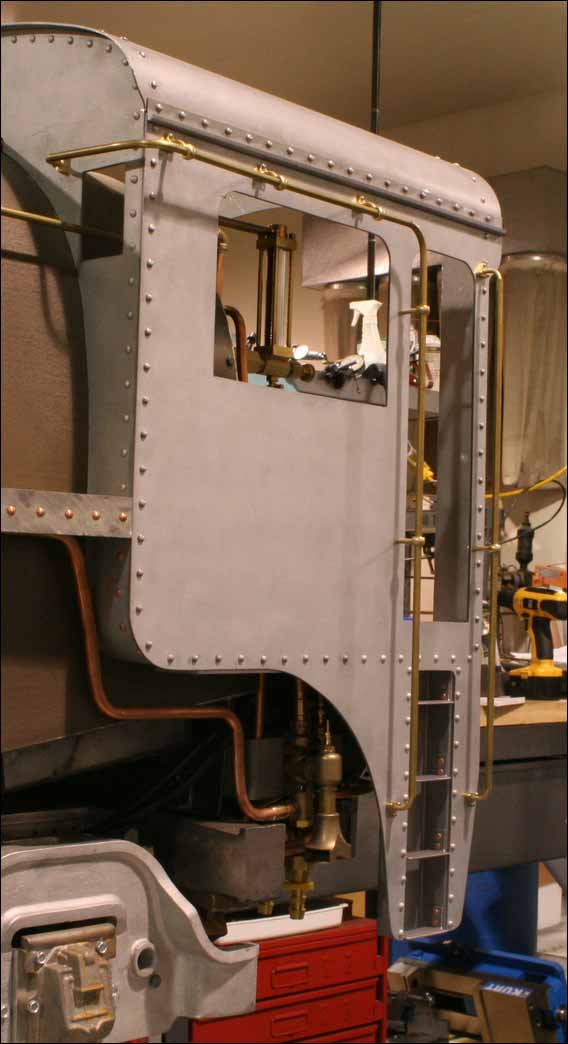

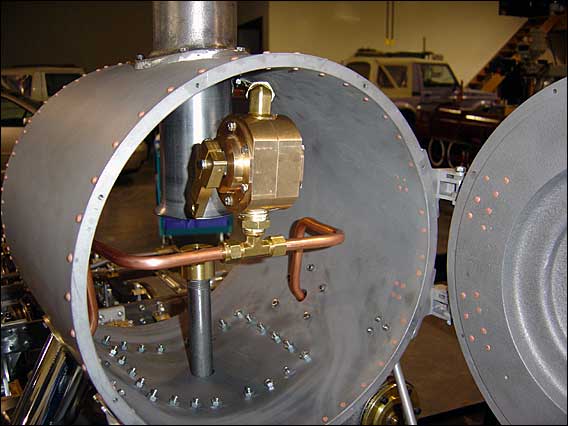

This Mikado project is now near completion. The boiler has been installed and all sheet-metal work is well underway and almost ready for plumbing. The boiler was manufactured by a certified manufacturer and has been stamped as certified across all North America.

Images taken May 2005:

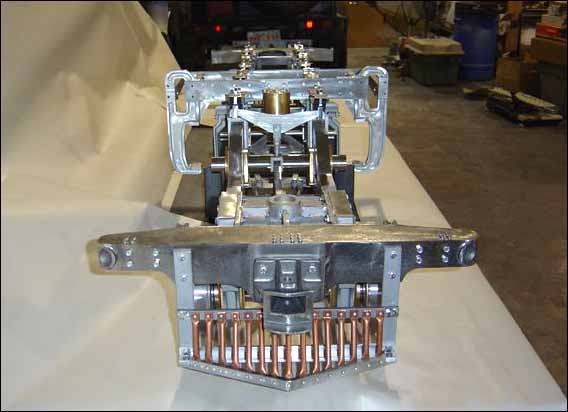

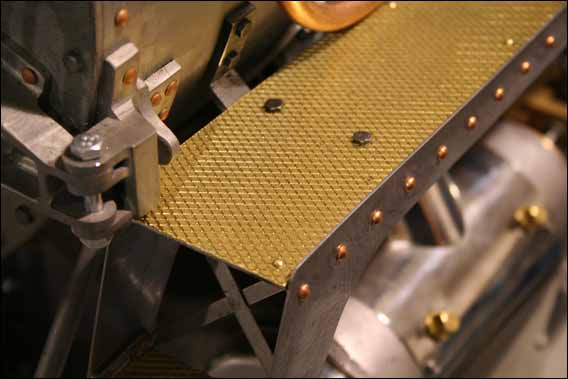

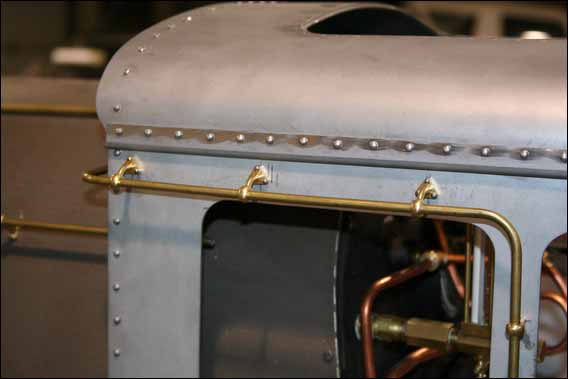

The tender is of all brass and stainless construction using copper rivets. The fuel oil tank is in place of the coal bunker.

Images taken March 2005:

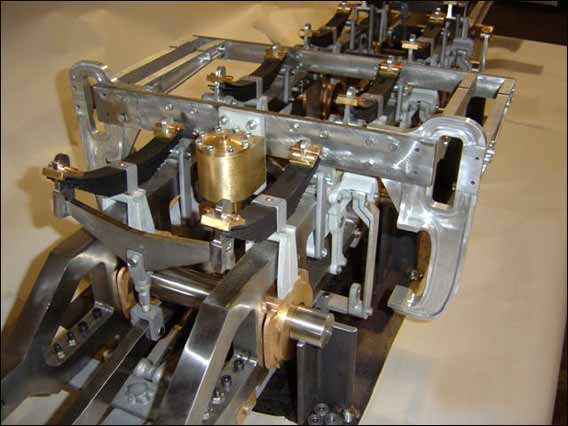

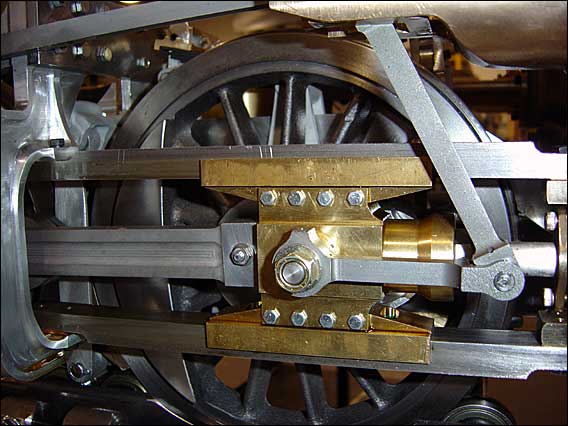

Close up of a three piece crosshead with replaceable shoes.

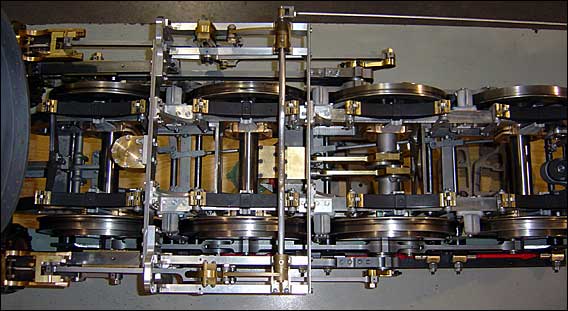

Images taken June 2004: